USING THE CAREER PATHWAY TOOL

Initial search results:

This page displays roles in the career pathway database listed from A-Z.

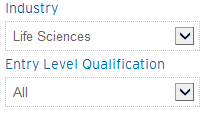

Filter options:

You can use the filter options on the left to refine your search by industry or sub sector, and by qualification entry level, or you can enter free text to search for a role title

Role information: Click on the  icon to display information about roles, including entry level requirements, competences, key activities, salary bands, case studies and useful links. A print version of the role is also available.

icon to display information about roles, including entry level requirements, competences, key activities, salary bands, case studies and useful links. A print version of the role is also available.

Create a pathway: double click on your chosen role in the A-Z search list to create a career pathway showing potential progression routes.

Navigation: Navigate forwards and backwards using the < or > icons or click return to search results.

Click the {x} to close this help screen.